HDR Brachytherapy

Cobalt-60 in HDR Brachytherapy

Confidence Through Experience

The well established and clinically proven isotope for all HDR Brachytherapy treatments.

Cobalt-60 sources are available for BEBIG Medical afterloaders.

HDR Brachytherapy Started with Cobalt-60

In 1962, Walstam introduced the first concept of a remote afterloader equipped with Co-60. Since its introduction, Co-60 has achieved tremendous success and has continued to evolve to support modern HDR brachytherapy needs. In 2003, BEBIG Medical successfully designed and introduced the first miniaturized Co-60 source. This design, modern even by today‘s standards, enables treatment with applicators of the smallest diameters and narrow curvatures. To date, more than 270 BEBIG Medical afterloaders equipped with Co-60 have been installed worldwide and continue to prove their outstanding reliability.

Clinically Sound with Proven Physics

The Co-60 source is not only clinically well proven, it is physically well understood and extensively analyzed as well. Accordingly, TG-43 data (Dosimetry of interstitial brachytherapy sources: Recommendations of the AAPM Radiation Therapy committee Task Group 43), dosimetric measurements, and Monte Carlo calculations are available and have been implemented in HDRplus and SagiPlan®. The treatment planning systems of BEBIG Medical are able to calculate dose distributions of Co-60 for all applicators shielded and unshielded.

Complete Range of Clinical Applications

Co-60 has been shown to be a good choice for treating gynecological, rectal, prostate, breast, esophagus, skin, and other body sites. BEBIG Medical provides customers with an expansive portfolio of applicators suitable for the use with Co-60 and Ir-192.

Favorable Dose to Organs at Risk

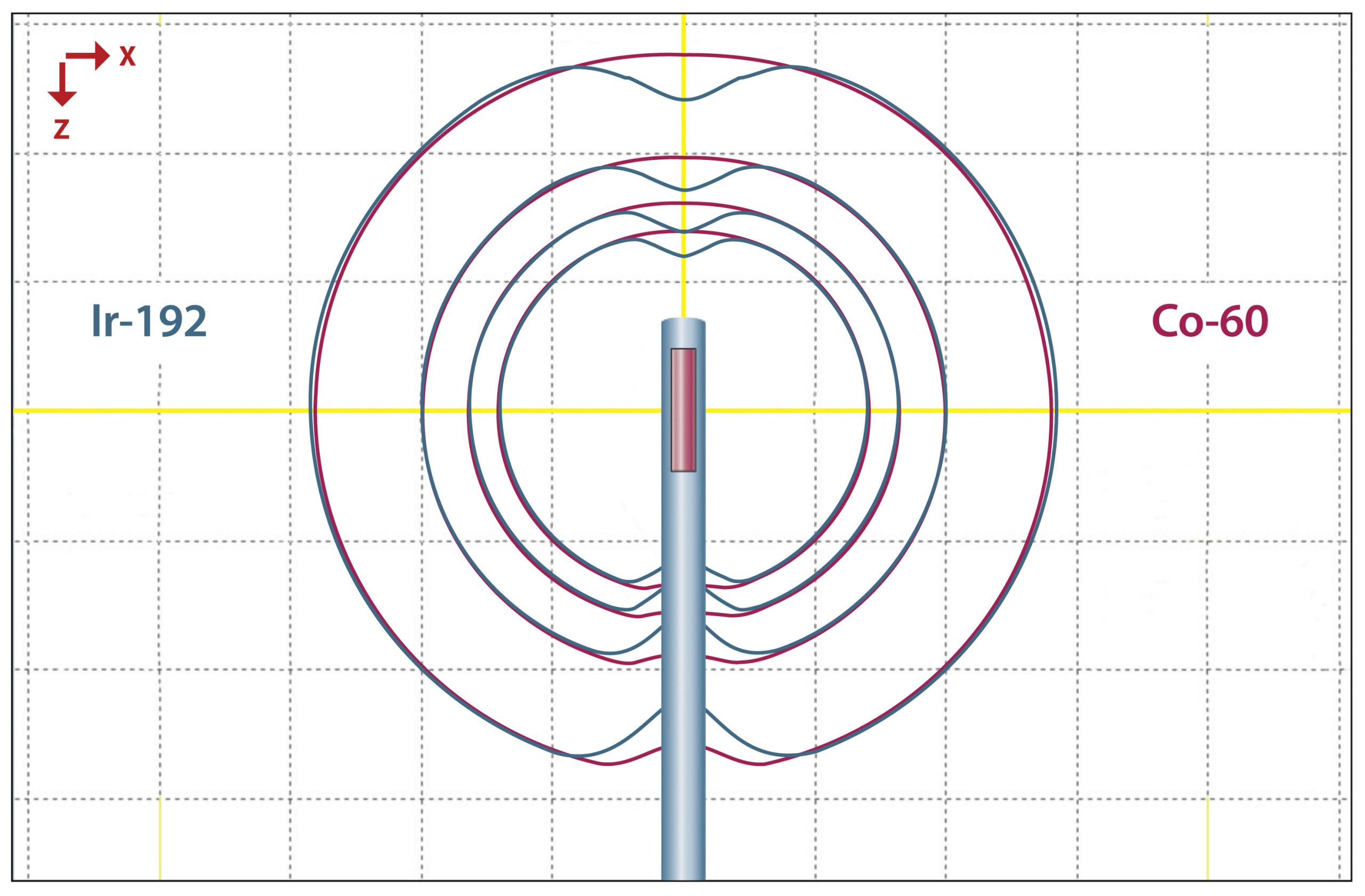

The treatment with Co-60 leads to lower dose to organs at risk (OAR) than with Ir-192. Due to its higher mean energy of 1.25 MeV, less scatter is produced and therefore, the radial dose function of Co-60 shows slightly smaller values than Ir-192 with 0.35 MeV (see figure 1 in fact sheet below). This leads to less dose to organs at risk or healthy tissue within approx. 20 cm from the source1.

Source Exchange Period up to 5 Years

Due to the long half-life of Co-60, the source can be used for up to 5 years which means that during the recommended working life of a single Co-60 source, approximately 20 source exchanges of Ir-192 would have to be performed. The significant time saved in performing quality assurance checks after each source exchange makes the use of Co-60 particuarly attractive for high volume clinics. Furthermore, Co-60 is the isotope of choice for countries with demanding logistics.

Adequate Treatment Time

The BEBIG Medical Co-60 source is loaded with an activity of up to 81.4 GBq which is significantly lower than an Ir-192 source, with up to 481 GBq. However, the Co-60 dose rate is only slightly lower due to the higher air kerma rate constant (306 vs. 110 μGy · m2 · GBq-1 · h-1). Therefore, the total treatment time with Co-60 is only slightly longer than with Ir-192. Nevertheless, if preferred, the source exchange period can be shortened to speed up treatment time..

Robust Capsule Design

The capsule design of the BEBIG Medical Co-60 source fulfills the demanding regulatory and governmental requirements of EU, North American, and other nations. Moreover, the unique source capsule shows outstanding wear resistance and a low friction factor due to well-engineered plasma Nitride hardening.The capsule and the source wire are connected by a hightech laser welding method and designed to stand 100,000 source transfers. This has been proven by stress tests in straight and curved applicators exceeding this figure to ensure safety and long-term precision². With 100,000 cycles in five years, a clinic could have theoretically up to 7 patients a day³ receiving a 10 channel interstitial treatment or 24 patients a day³ for the Treatment with a three-channel applicator. However, the user is always informed about the current numbers of cycles by the afterloaders software to ensure compliance with the maximum value.